BS 4504 316L Plate Flange DN50 PN10

- FOB PriceUSD 1 - 1,700/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

| Material: |

Stainless Steel 316L, etc

| Size: |

2" (DN50)

| Type: | |

| Place of Origin: |

Zhejiang, China (Mainland)

| Connection: |

Welding

| Brand Name: |

Yaang

|

| Standard: |

BS, etc

| Shape: |

Round

| Standard or Nonstandard: |

Standard

|

| Technics: |

Forged

|

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

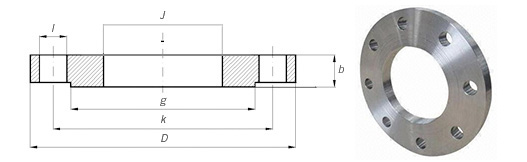

BS 4504 316L Plate Flange

1. Material: Stainless Steel 316L, etc

2. Size: 2" (DN50)

3. Standard: BS, etc

4. Pressure: PN6, PN10, PN16, PN25, PN40, PN64, etc

BS 4504: British Standard BS 4504 : Section 3.1 : 1989 - Circular Flanges for Pipes, Valves and Fittings (PN Designated), Specification for Steel Flanges. This covers flanges in nominal pressure ranges PN 2.5 to PN 40 and nominal sizes up to DN 4000 (see table below). BS 4504 substantially agrees with ISO 7005-1 : 1992 (E) Part 1 : Steel Flanges.

BS 4504 : 1969 is still commonly used. This older standard allows for manufacture from bar, whereas the latest standard specifies that forging or plate are to be used, which can be significantly more expensive. There are minor differences in dimensions between the two versions. The following tables are based on the later version.

A bs 4504 316l plate flange is a flat, circular disk that is welded onto the end of a pipe and allows it to be bolted to another pipe. Typically used in fuel and water pipelines, the two plate flanges will be bolted together with a gasket in between them. The plate flange will have bolt holes all around the perimeter and will be used to create junctions, tees and joints.

Plate flanges are fabricated mainly from quality mill steel plates. They are similar to slip on flange but without the hub and also require two fillet welds. Mostly the plate flanges are produced in accordance with DIN, JIS, UNI, BS or GOST standards.

When building a pipeline, the length of the pipes used are not always known. By manufacturing the pipes separate from the plate flanges, the welders can cut the pipes to length and weld a plate flanges in place to join the pipes at any needed length. The plates can also be welded to the pipe on a slight bias, allowing two pipes to be joined that may not be precisely lined up.

1. Material: Stainless Steel 316L, etc

2. Size: 2" (DN50)

3. Standard: BS, etc

4. Pressure: PN6, PN10, PN16, PN25, PN40, PN64, etc

BS 4504: British Standard BS 4504 : Section 3.1 : 1989 - Circular Flanges for Pipes, Valves and Fittings (PN Designated), Specification for Steel Flanges. This covers flanges in nominal pressure ranges PN 2.5 to PN 40 and nominal sizes up to DN 4000 (see table below). BS 4504 substantially agrees with ISO 7005-1 : 1992 (E) Part 1 : Steel Flanges.

BS 4504 : 1969 is still commonly used. This older standard allows for manufacture from bar, whereas the latest standard specifies that forging or plate are to be used, which can be significantly more expensive. There are minor differences in dimensions between the two versions. The following tables are based on the later version.

A bs 4504 316l plate flange is a flat, circular disk that is welded onto the end of a pipe and allows it to be bolted to another pipe. Typically used in fuel and water pipelines, the two plate flanges will be bolted together with a gasket in between them. The plate flange will have bolt holes all around the perimeter and will be used to create junctions, tees and joints.

Plate flanges are fabricated mainly from quality mill steel plates. They are similar to slip on flange but without the hub and also require two fillet welds. Mostly the plate flanges are produced in accordance with DIN, JIS, UNI, BS or GOST standards.

When building a pipeline, the length of the pipes used are not always known. By manufacturing the pipes separate from the plate flanges, the welders can cut the pipes to length and weld a plate flanges in place to join the pipes at any needed length. The plates can also be welded to the pipe on a slight bias, allowing two pipes to be joined that may not be precisely lined up.

Composition

Table 1. Composition ranges for 316L stainless steel.

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

316L

Min

-

-

-

-

-

16.0

2.00

10.0

-

Max

0.03

2.0

0.75

0.045

0.03

18.0

3.00

14.0

0.10

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

| |

316L

|

Min

|

-

|

-

|

-

|

-

|

-

|

16.0

|

2.00

|

10.0

|

-

|

Max

|

0.03

|

2.0

|

0.75

|

0.045

|

0.03

|

18.0

|

3.00

|

14.0

|

0.10

|

Mechanical Properties

Table 2. Mechanical properties of 316L stainless steel.

Grade

Tensile Str

(MPa) min

Yield Str

0.2% Proof

(MPa) min

Elong

(% in 50mm) min

Hardness

Rockwell B (HR B) max

Brinell (HB) max

316L

485

170

40

95

217

Table 2. Mechanical properties of 316L stainless steel.

Grade

|

Tensile Str

(MPa) min |

Yield Str

0.2% Proof (MPa) min |

Elong

(% in 50mm) min |

Hardness

| |

Rockwell B (HR B) max

|

Brinell (HB) max

| ||||

316L

|

485

|

170

|

40

|

95

|

217

|

Grade Specification Comparison

Table 4. Grade specifications for 316L stainless steel.

Grade

UNS

No

Old British

Euronorm

Swedish

SS

Japanese

JIS

BS

En

No

Name

316L

S31603

316S11

-

1.4404

X2CrNiMo17-12-2

2348

SUS 316L

Table 4. Grade specifications for 316L stainless steel.

Grade

|

UNS

No |

Old British

|

Euronorm

|

Swedish

SS |

Japanese

JIS | ||

BS

|

En

|

No

|

Name

| ||||

316L

|

S31603

|

316S11

|

-

|

1.4404

|

X2CrNiMo17-12-2

|

2348

|

SUS 316L

|

APPLICATIONS:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Plate flange is most widely used in fuel and water pipelines, where two flange plates are bolted together with a gasket in between them. The flange plate will have bolt holes all around the perimeter and will be used to create junctions, tees and joints.

APPLICATIONS:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Plate flange is most widely used in fuel and water pipelines, where two flange plates are bolted together with a gasket in between them. The flange plate will have bolt holes all around the perimeter and will be used to create junctions, tees and joints.

BS 4504 316L Plate Flange's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality BS 4504 316L Plate Flange DN50 PN10.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|