ASTM A403 MSS SP-43 WP304 Stub End DN100 SCH40S

- FOB PriceUSD 1 - 1,700/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

WP304 Stub End

1) Good Quality

2) Competitive Price

4) Nice packing

WP304 Stub End

1) Good Quality

2) Competitive Price 4) Nice packing

ASTM A403 MSS SP-43 WP304 Stub End DN100 SCH40S

1. Material: 304 Stainless Steel

2.THK: Sch40s

| 304 Lap Joint Stub End | ||

| 1 | Type: |

Stub End

|

| 2 | Size: | 1/2" - 60" |

| 3 | Wall thickness: | Sch5S-Sch160, XS, XXS(1.2mm~34mm) |

| 4 | Standard: | GB, JIS, BS, DIN, ANSI, etc |

| 5 | Material: |

Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, 321, 347, 904L

Super & Duplex Stainless Steel: UNS 31803, UNS 32750 ,UNS 32760, etc.

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51, etc

Super Duplex Stainless Steel: S32750/2507/F53/F55, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

|

| 6 | Pressure ratings: |

PN: 6, 10, 16, 25, 40, 64 and 160, 5K-40K and so on

|

| 7 | Sealing surface: | Sand Rolling, Sand Blasting, Acid Cleaning. |

| 8 | Marking: | according to client's requirement. |

| 9 | Application: | petroleum, chemical, power, gas, water, linepipe, heat exchanger, shipbuilding, construction, etc. |

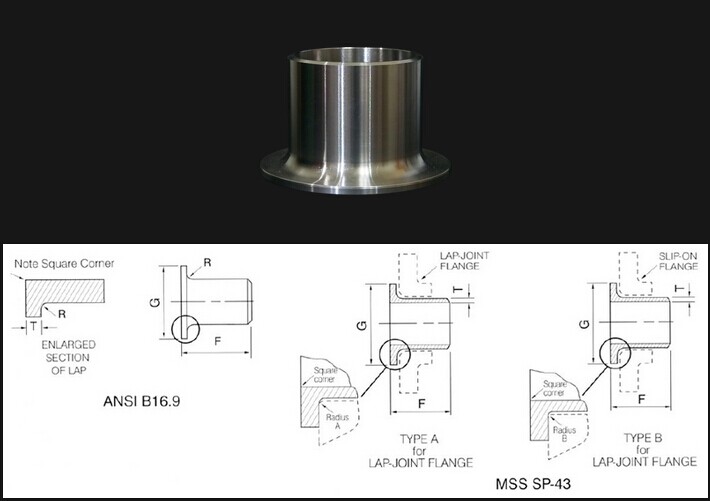

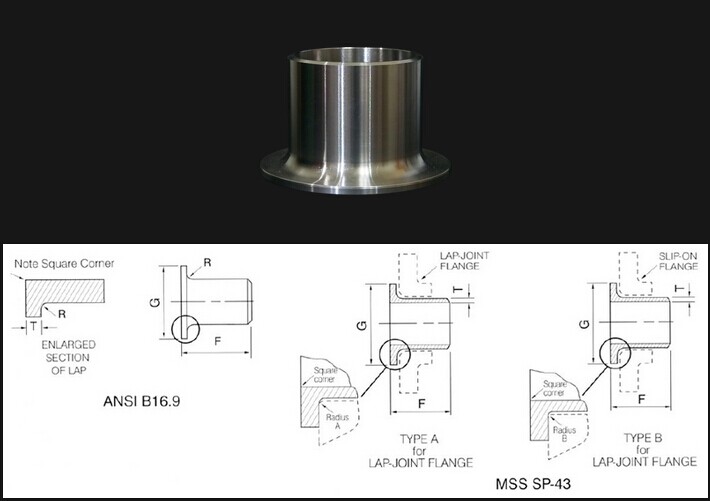

304 Lap Joint Stub End is fitting used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the 304 Stub End. The gasket surface of the 304 Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

A 304 lap joint stub end and it associated slip on flange in a piping system allows quick disconnection of the particular section involved. 304 stub end is installed in pairs and mated together with two lap joint flanges. The surface of the stub end has a phonographic serrated gasket surface which prevents leakage at the joint. Using 304 stub end allows sections of the line to be opened for cleaning, inspection or quick replacement etc, without the need to re-weld. There lap joints stub ends are two basic types of stub end, A.S.A.long barrel, and M.S.S. short barrel. Under certain design criteria such as temperature or pressure etc, it is not acceptable to have the joint between 304 stub end and pipe in close proximity with the flange joint; in these applications A.S.A. types are used.

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes and pipe fittings with special specifications according to customers’ requirements.

If any inquiry, please feel free to contact by email sales@yaang.com