EN1092-1 Type 11 304L WNRF Flange DN25 PN40 SCH10S

EN1092-1 Type 11 304L WNRF Flange DN25 PN40 SCH10S

1. Material: 304L (1.4306), etc

2. Size: 1" (DN25), SCH10S

Quick Details

- Size: 1" (DN25)

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Standard or Nonstandard: Standard

- Material: 304L (1.4306), etc

- Technics: Forging

- Type: 304L WNRF Flange

- Shape: Round

- Standard: ASME, ANSI, etc

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 15 days after receiving the deposit |

Specifications

1. Material: 304L (1.4306), etc

2. Size: 1" (DN25), SCH10S

3. Standard: ASME B16.5, JIS, DIN

4. Type: 304L WNRF Flange

5. Pressure: PN40

| Euronorm | Nom. | AISI / ASTM / UNS |

| 1.4306 | X2CrNi19-11 | 304L S30403 |

Chemical Composition of Grade 304L Stainless Steel

| Grades | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | Cu | Other |

| ACX 232 | <=0.030 | <=0.75 | <=2.00 | <=0.040 | <=0.030 | 18.00-20.00 | 10.00-11.00 | - | - | - | N(ppm) <700 |

| EN1092-1 Type 11 304L WNRF Flange | ||

| 1 | Material: |

Stainless Steel: such as 304, 304L, 316, 316L, 321 ,

310S, 904L, S31803, F51 and so on.

|

| 2 | Standard: | GB, JIS, BS, DIN, ANSI and Non standard |

| 3 | ANSI Class: | 15, 030, 040, 060, 090 |

| 4 | Size: | 1/2" - 24" |

| 5 | Type: |

Slip-on flanges, Blind flanges, Lap joint flanges,

Welding neck flanges,Plate flange,

Socket welding flanges and Treaded flanges

|

| 6 | Pressure ratings: |

Class: 150 300 400 600 900 1500 and 2500

PN: 6 10 16 25 40 64 and 160 , 5K - 40K and so on

|

| 7 | Sealing surface: | FF ,RF, LJ, FM , R.T.J , R.J and so on . |

| 8 | Production process: | raw material-cutting-heating-forging-heat treatment-maching-inspection. |

| 15 | Application: |

petroleum, chemical, power, gas, water, linepipe, heat exchanger,

shipbuilding, construction, etc.

|

| 16 | Tolerance: | not less than +_8% of normal wall thickness. |

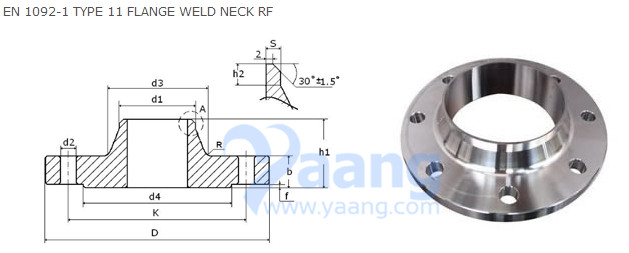

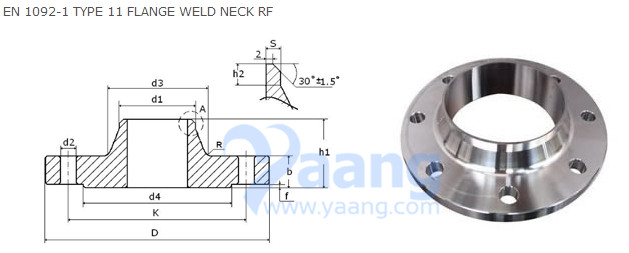

| EN 1092-1 TYPE 11 PN40 WNRF FLANGE | |||||||||||||||

| Rated Diameter | Flange | Neck | Raised face | Screws | Weight (7,85 Kg/dm3) | ||||||||||

| d1 | k | D | b | h1 | d3 | s | r | h2 | d4 | f | d2 | Thread | Bolt holes | Kg | |

| 15 | 21,3 | 65 | 95 | 16 | 38 | 32 | 2,00 | 4 | 6 | 45 | 2 | 14 | M12 | 4 | 0,768 |

| 20 | 26,9 | 75 | 105 | 18 | 40 | 40 | 2,30 | 4 | 6 | 58 | 2 | 14 | M12 | 4 | 1,090 |

| 25 | 33,7 | 85 | 115 | 18 | 40 | 46 | 2,60 | 4 | 6 | 68 | 2 | 14 | M12 | 4 | 1,300 |

| 32 | 42,4 | 100 | 140 | 18 | 42 | 56 | 2,60 | 6 | 6 | 78 | 2 | 18 | M16 | 4 | 1,910 |

| 40 | 48,3 | 110 | 150 | 18 | 45 | 64 | 2,60 | 6 | 7 | 88 | 3 | 18 | M16 | 4 | 2,150 |

| 50 | 60,3 | 125 | 165 | 20 | 48 | 75 | 2,90 | 6 | 8 | 102 | 3 | 18 | M16 | 4 | 2,850 |

| 65 | 76,1 | 145 | 185 | 22 | 52 | 90 | 2,90 | 6 | 10 | 122 | 3 | 18 | M16 | 8 | 3,680 |

| 80 | 88,9 | 160 | 200 | 24 | 58 | 105 | 3,20 | 8 | 12 | 138 | 3 | 18 | M16 | 8 | 4,780 |

| 100 | 114,3 | 190 | 235 | 24 | 65 | 134 | 3,60 | 8 | 12 | 162 | 3 | 22 | M20 | 8 | 6,460 |

| 125 | 139,7 | 220 | 270 | 26 | 68 | 162 | 4,00 | 8 | 12 | 188 | 3 | 26 | M24 | 8 | 8,860 |

| 150 | 168,3 | 250 | 300 | 28 | 75 | 192 | 4,50 | 10 | 12 | 218 | 3 | 26 | M24 | 8 | 11,700 |

| 200 | 219,1 | 320 | 375 | 34 | 88 | 244 | 6,30 | 10 | 16 | 285 | 3 | 30 | M27 | 12 | 21,000 |

| 250 | 273,0 | 385 | 450 | 38 | 105 | 306 | 7,10 | 12 | 18 | 345 | 3 | 33 | M30 | 12 | 34,200 |

| 300 | 323,9 | 450 | 515 | 42 | 115 | 362 | 8,00 | 12 | 18 | 410 | 4 | 33 | M30 | 16 | 47,600 |

| 350 | 355,6 | 510 | 580 | 46 | 125 | 408 | 8,80 | 12 | 20 | 465 | 4 | 36 | M33 | 16 | 69,300 |

| 400 | 406,4 | 585 | 660 | 50 | 135 | 462 | 11,00 | 12 | 20 | 535 | 4 | 39 | M36 | 16 | 98,000 |

| 450 | 457,0 | 610 | 685 | 57 | 135 | 500 | 12,50 | 12 | 20 | 560 | 4 | 39 | M36 | 20 | 105,000 |

| 500 | 508,0 | 670 | 755 | 57 | 140 | 562 | 14,20 | 12 | 20 | 615 | 4 | 42 | M39 | 20 | 130,000 |

| 600 | 610,0 | 795 | 890 | 72 | 150 | 666 | 16,00 | 12 | 20 | 735 | 5 | 48 | M45 | 20 | 209,000 |

1. SURFACE FINISH FACING TYPES A, B1, B2 etc

| |||||||||||||||

2. FLANGE MARKING: LOGO EN 1092-1 / 11 B1 / DN100 / PN40 / P245GH / HEAT NUMBER

| |||||||||||||||

Weld neck flange is a type of pipe flange that incorporates a cast-in neck that is welded to the pipe. Unlike a plain flange that is slipped over the pipe prior to being welded into place, a weld neck flange has a spout-like neck that is beveled to match up to the pipe. Once the pipe is beveled to match the weld neck flange, a perfect V shape is created in which a butt weld is placed to connect the two components.

APPLICATIONS:

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|