MSS-SP43 ASTM A815 UNS31803 GR2205 Welded Stub End BW SHOT LENGTH SCH10S 600NB

- FOB PriceUSD 1 - 1,700/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Material: Duplex 2205 (UNS S31803)

- Technics: Cold forming

- Type: Stub End

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Connection: Welding

- Head Code: Round

- Size: 24 Inch (DN600)

Packaging & Delivery

| Packaging Details: | fumigation free plywood cases or as per customers' requests |

|---|---|

| Delivery Detail: | Delivery after receiving deposit |

Specifications

MSS-SP43 ASTM A815 UNS3103 GR2205 Welded Stub End BW SHOT LENGTH

Size: 24 Inch (DN600)

Thk: SCH10S (6.35MM)

Material: Duplex 2205 (UNS S31803)

Duplex stainless steel 2205 Chemical Composition %

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

| |

2205 (S31803)

|

Min

Max

|

-

0.030

|

-

2.00

|

-

1.00

|

-

0.030

|

-

0.020

|

21.0

23.0

|

2.5

3.5

|

4.5

6.5

|

0.08

0.20

|

Type

| 2205 Stub End |

Standard

|

ASME B16.9, MSS SP-43, GB/T13401, etc.

|

Size

|

1/2"-48"(DN15-DN600)

|

Wall thickness

|

SCH5S-SCH40S

|

Type

|

Type A, Type B,Type C

|

Surface treatment

|

Lathe finish&Abrasive blasting

|

Stainless steel

|

304, 304L,304H, 316, 316L,309S,310S, 321,321H,347H,316Ti

|

Duplex steel

|

2205, etc

|

Super duplex steel

|

2507, etc

|

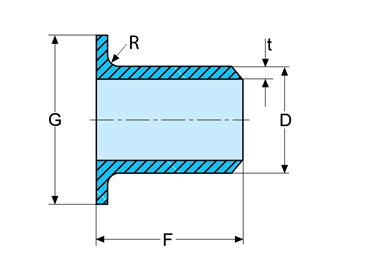

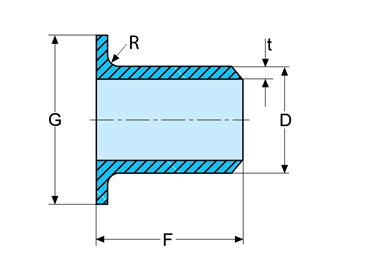

| Nominal pipe size | Sch.* | Dimensions in mm | Weight | ASTM | ASTM | UNS | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| in. | D | t | G | F | R. max. | kg/pce | 304/304L | 316/316L | S31803 | |

| 1/2 | 10s 40s | 21.3 21.3 | 2.11 2.77 | 34.9 34.9 | 50.8 50.8 | 3.18 3.18 | 0.070

0.090

| ●

●

| ●

●

| - - |

| 3/4 | 10s 40s | 26.7 26.7 | 2.11 2.87 | 42.9 42.9 | 50.8 50.8 | 3.18 3.18 | 0.100

0.120

| ●

●

| ●

●

| ●

●

|

| 1 | 10s 40s | 33.4 33.4 | 2.77 3.38 | 50.8 50.8 | 50.8 50.8 | 3.18 3.18 | 0.160

0.170

| ●/▲

●

| ●/▲

●

| ●

●

|

| 1 ¼ | 10s 40s | 42.2 42.2 | 2.77 3.56 | 63.5 63.5 | 50.8 50.8 | 4.76 4.76 | 0.220

0.250

| ●

●

| ●

●

| ● - |

| 1 ½ | 10s 40s | 48.3 48.3 | 2.77 3.68 | 73.0 73.0 | 50.8 50.8 | 6.35 6.35 | 0.250

0.310

| ●/▲

●

| ●/▲

●

| ●

●

|

| 2 | 10s 40s | 60.3 60.3 | 2.77 3.91 | 92.1 92.1 | 63.5 63.5 | 7.94 7.94 | 0.430

0.610

| ●/▲

●

| ●/▲

●

| ●

●

|

| 2 ½ | 10s 40s | 73.0 73.0 | 3.05 5.16 | 104.8 104.8 | 63.5 63.5 | 7.94 7.94 | 0.570

0.800

| ●/▲

●

| ●/▲

●

| ● - |

| 3 | 10s 40s | 88.9 88.9 | 3.05 5.49 | 127.0 127.0 | 63.5 63.5 | 9.53 9.53 | 0.730

1.130

| ●/▲

●

| ●/▲

●

| ● - |

| 4 | 10s 40s | 114.3 114.3 | 3.05 6.02 | 157.2 157.2 | 76.2 76.2 | 11.11 11.11 | 1.090

1.870

| ●/▲

●

| ●/▲

●

| ● - |

| 5 | 10s 40s | 141.3 141.3 | 3.40 6.55 | 185.7 185.7 | 76.2 76.2 | 11.11 11.11 | 1.470

2.280

| ●/▲

●

| ●/▲

●

| - - |

| 6 | 10s 40s | 168.3 168.3 | 3.40 7.11 | 215.9 215.9 | 88.9 88.9 | 12.70 12.70 | 2.150

3.570

| ●/▲

●

| ●/▲

●

| ●/▲

●

|

| 8 | 10s 40s | 219.1 219.1 | 3.76 8.18 | 269.9 269.9 | 101.6 101.6 | 12.70 12.70 | 3.220

6.070

| ●/▲

●/▲

| ●/▲

▲

| ▲ - |

| 10 | 10s 40s | 273.1 273.1 | 4.19 9.27 | 323.9 323.9 | 127.0 127.0 | 12.70 12.70 | 4.700 9.550 | ▲ ▲ | ▲ ▲ | ▲ - |

| 12 | 10s 40s | 323.9 323.9 | 4.57 9.53 | 381.0 381.0 | 152.4 152.4 | 12.70 12.70 | 7.110 14.290 | ▲ ▲ | ▲ ▲ | ▲ - |

| 14 | 10s STD | 355.6 355.6 | 4.78 9.53 | 412.8 412.8 | 152.4 152.4 | 12.70 12.70 | 7.800 15.500 | ▲ - | ▲ ▲ | - - |

| 16 | 10s STD | 406.4 406.4 | 4.78 9.53 | 469.9 469.9 | 152.4 152.4 | 12.70 12.70 | 9.000 17.380 | ▲ - | ▲ ▲ | - - |

| 18 | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 11.000 | ▲ | ▲ | - |

| 20 | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 13.500 | ▲ | ▲ | - |

| 24 | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 19.000 | ▲ | ▲ | - |

* Schedule

UNS31803 GR2205 Stub End

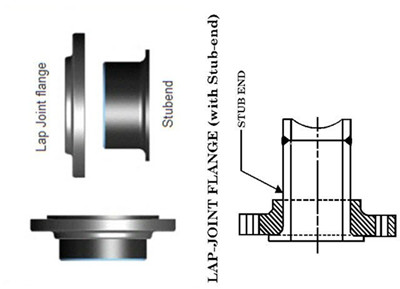

What are they?

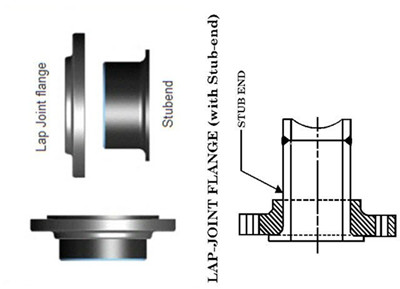

UNS31803 GR2205 Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

UNS31803 GR2205 Stub Ends' TypesUNS31803 GR2205 Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

UNS31803 GR2205 Stub Ends are available in two standard lengths, MSS and ANSI.UNS31803 GR2205 Stub Ends are normally provided with a standard weld bevel

UNS31803 GR2205 Stub Ends dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality MSS-SP43 ASTM A815 UNS31803 GR2205 Welded Stub End BW SHOT LENGTH SCH10S 600NB.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email sales@yaang.com

Related products:More>>

|  |