316L Straight Hex Nipple Male NPT 1 Inch 150LBS

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Material: 316L

- Technics: Forged

- Type: Straight Hex Nipple

- Place of Origin: Zhejiang, China (Mainland)

- Model Number: 316L-Straight-Hex-Nipple-Male-NPT

- Brand Name: Yaang

- Size: 1 inch

- Pressure: 150LBS

- Thread: Male NPT

Packaging & Delivery

| Packaging Details: |

Plywood case or fumigated woodern case or as per customers' requests.

|

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

Type: Socket Weld Pipe Union

Material: 316L

Size: 1 inch

Pressure: 150LBS

Thread: Male NPT

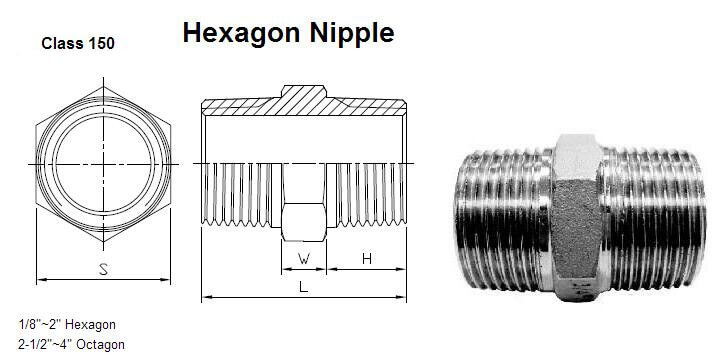

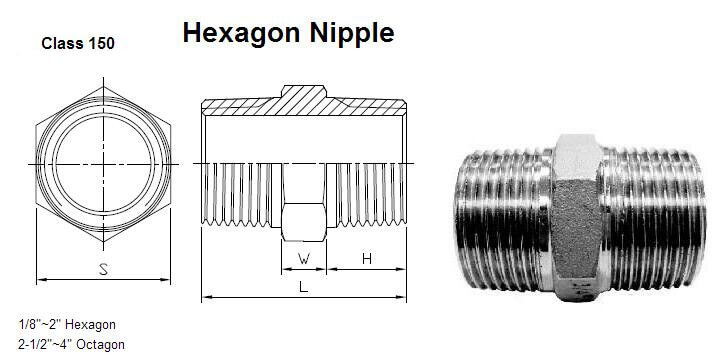

A pipe nipple is a short pipe typically with male threading at both ends to connect two other pipes or fittings. However, the size or type of nipple greatly depends on the application for which it is being used for. It is important to get the proper nipple that is needed for the job. There are three specific types of short, or barrel nipples that can cause confusion on how to use in their applications. Hex nipples typically have male threading on both ends of a hexagnoal bolt shape in the center. This allows for easy torquing, tightening, or Hex nipplesloosening using a wrench. Hex nipples come in handy during applications that require you to connect two brass or steel pipes, both with female ends. Common applications involve automotive, plumbing, or industrial.

Standard Pattern

Standard Pattern

| Description | |||

| Product Name | hexagon nipple | ||

| Material | SUS201, SUS304, SUS316, (SS201 SS304 SS316), etc | ||

| Connection type | male | ||

| Thread | NPT BSPT BSP | ||

| Size | 1/4 to 4 inches | ||

| Medium | Water, oil and gas | ||

| Pressure | 150LBS | ||

| Standard | With non-standard fittings | ||

| OEM | Customized logos are accepted | ||

| Delivery time | normally 30 days after receipt of advanced payment | ||

| Productivity | 150000 ton per year | ||

| SIZE | 1/8" | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" | ||||||||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | |

| W | 5.7 | 0.22 | 6 | 0.24 | 6.1 | 0.24 | 7.6 | 0.3 | 8.4 | 0.33 | 8.3 | 0.33 | 10 | 0.39 | 10.2 | 0.4 | 10.6 | 0.42 | 13.1 | 0.52 | 13 | 0.51 | 14.5 | 0.57 |

| H | 12.2 | 0.48 | 13 | 0.51 | 13 | 0.51 | 17.2 | 0.68 | 17.6 | 0.69 | 20.4 | 0.8 | 20.8 | 0.82 | 20.7 | 0.81 | 22 | 0.87 | 25 | 0.98 | 27.5 | 1.08 | 30.3 | 1.19 |

| S | 13.3 | 0.52 | 15.2 | 0.6 | 18.5 | 0.73 | 23 | 0.91 | 29 | 1.14 | 35 | 1.38 | 44 | 1.73 | 50 | 1.97 | 62 | 2.44 | 78 | 3.07 | 91 | 3.58 | 117 | 4.61 |

| L | 30 | 1.18 | 32 | 1.26 | 32 | 1.26 | 42 | 1.65 | 43.5 | 1.71 | 49 | 1.93 | 51.5 | 2.03 | 51.5 | 2.03 | 54.5 | 2.15 | 63 | 2.48 | 68 | 2.68 | 75 | 2.95 |

Tolerance: +0.5mm(1/8"~2")

+0.8mm(2-1/2"~4")

Economic Pattern| SIZE | 1/8" | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" | ||||||||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | |

| W | 5.6 | 0.22 | 6 | 0.24 | 6 | 0.24 | 7.6 | 0.3 | 8.5 | 0.33 | 8 | 0.31 | 9.5 | 0.37 | 9.5 | 0.37 | 10.5 | 0.41 | 13 | 0.51 | 13 | 0.51 | 15 | 0.59 |

| H | 9 | 0.35 | 11 | 0.43 | 11 | 0.43 | 14 | 0.55 | 14 | 0.55 | 17.5 | 0.69 | 18 | 0.71 | 18.5 | 0.73 | 20 | 0.79 | 22.5 | 0.89 | 25 | 0.98 | 28 | 1.1 |

| S | 13 | 0.51 | 15 | 0.59 | 18 | 0.71 | 23 | 0.91 | 29 | 1.14 | 35 | 1.38 | 45 | 1.77 | 50 | 1.97 | 62 | 2.44 | 78 | 3.07 | 91 | 3.58 | 118 | 4.65 |

| L | 26 | 1.02 | 30 | 1.18 | 30 | 1.18 | 40 | 1.57 | 40.5 | 1.59 | 48 | 1.89 | 49.5 | 1.95 | 49.5 | 1.95 | 52.5 | 2.07 | 60 | 2.36 | 65 | 2.56 | 71 | 2.8 |

Tolerance: +0.5mm(1/8"~2")

+0.8mm(2-1/2"~4")

Typical Applications:

- Food and Beverage

- Irrigation and Pumping

- Petrochemical

- Geothermal

- Marine

- Agriculture and Machinery

- Motoring

If any inquiry, please feel free to contact by email sales@yaang.com

Chemical Composition and Mechanical Property For 316L

| |||||||||||

Steel Grade

|

Chemical Composition

|

Mechanical Performance

| |||||||||

C(Max)

|

Si(Max)

|

Mn(Max)

|

P(Max)

|

S(Max)

|

Ni

|

Cr

|

Mo

|

N(Max)

|

Tensile Strength

(Min) |

Yield Strength

(Min) | |

Mpa

|

Mpa

| ||||||||||

316L

|

0.03

|

0.75

|

2.00

|

0.045

|

0.03

|

10.0–14.0

|

16.0–18.0

|

2.00–3.00

|

0.1

|

485

|

170

|

Related products:More>>

|  |