ASME B16.9 ASTM A403 304L Reducing Cross DN50 - DN25 Sch40S

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Material: 304L

- Technics: Forged

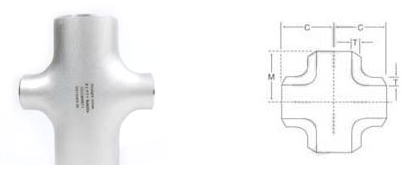

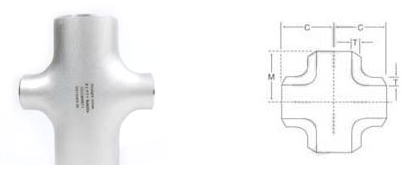

- Type: Reducing Cross

- Place of Origin: Zhejiang, China (Mainland)

- Model Number: 304L-Reducing-Cross-DN50-Sch40S

- Brand Name: Yaang

- WT: Sch40S

- Size: DN50×DN25

Packaging & Delivery

| Packaging Details: |

Plywood case or fumigated woodern case or as per customers' requests.

|

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

Type: Reducing Cross

Material: 304L

WT: Sch40S

Size: 50×25

A pipe cross is a kind of pipe fitting. It is used in the place where four pipes meet together. The pipe cross may have one inlet and three outlets, or there inlets and one outlet. The diameter of the outlet and inlet can be the same and can also be different. That is to say, straight cross and reducing cross are both availabe.

China Pipe Cross Manufacturer yaang supplies ASME B16.9 ASTM A403 304L Reducing Cross, DN50×DN25, Sch40S.

Composition ranges for 304 grade stainless steel

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

| |

304

|

min.

max.

|

-

0.08

|

-

2.0

|

-

0.75

|

-

0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

10.5

|

-

0.10

|

304L

|

min.

max.

|

-

0.030

|

-

2.0

|

-

0.75

|

-

0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

12.0

|

-

0.10

|

304H

|

min.

max.

|

0.04

0.10

|

-

2.0

|

-

0.75

|

-0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

10.5

|

-

|

Mechanical properties of 304 grade stainless steel

Grade

|

Tensile Strength (MPa) min

|

Yield Strength 0.2% Proof (MPa) min

|

Elongation (% in 50mm) min

|

Hardness

| |

Rockwell B (HR B) max

|

Brinell (HB) max

| ||||

304

|

515

|

205

|

40

|

92

|

201

|

304L

|

485

|

170

|

40

|

92

|

201

|

304H

|

515

|

205

|

40

|

92

|

201

|

304H also has a requirement for a grain size of ASTM No 7 or coarser.

| |||||

Physical properties of 304 grade stainless steel in the annealed condition

Grade

|

Density (kg/m3)

|

Elastic Modulus (GPa)

|

Mean Coefficient of Thermal Expansion (μm/m/°C)

|

Thermal Conductivity (W/m.K)

|

Specific Heat 0-100°C (J/kg.K)

|

Electrical Resistivity (nΩ.m)

| |||

0-100°C

|

0-315°C

|

0-538°C

|

at 100°C

|

at 500°C

| |||||

304/L/H

|

8000

|

193

|

17.2

|

17.8

|

18.4

|

16.2

|

21.5

|

500

|

720

|

Grade specifications for 304 grade stainless steel

Grade

|

UNS No

|

Old British

|

Euronorm

|

Swedish SS

|

Japanese JIS

| ||

BS

|

En

|

No

|

Name

| ||||

304

|

S30400

|

304S31

|

58E

|

1.4301

|

X5CrNi18-10

|

2332

|

SUS 304

|

304L

|

S30403

|

304S11

|

-

|

1.4306

|

X2CrNi19-11

|

2352

|

SUS 304L

|

304H

|

S30409

|

304S51

|

-

|

1.4948

|

X6CrNi18-11

|

-

|

-

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

| |||||||

| Nominal Diameter | Outside Diameter | Center to End | |||||

|---|---|---|---|---|---|---|---|

| D1 | D2 | ||||||

| DN | NPS | Series A | Series B | Series A | Series B | C | M |

| 15×15 | 1/2×1/2 | 21.3 | 18 | 21.3 | 18 | 25 | 25 |

| 15×10 | 1/2×3/8 | 21.3 | 18 | 17.3 | 14 | 25 | 25 |

| 15×8 | 1/2×1/4 | 21.3 | 18 | 13.7 | 10 | 25 | 25 |

| 20×20 | 3/4×3/4 | 26.9 | 25 | 26.9 | 25 | 29 | 29 |

| 20×15 | 3/4×1/2 | 26.9 | 25 | 21.3 | 18 | 29 | 29 |

| 20×10 | 3/4×3/8 | 26.9 | 25 | 17.3 | 14 | 29 | 29 |

| 25×25 | 1×1 | 33.7 | 32 | 33.7 | 32 | 38 | 38 |

| 25×20 | 1×3/4 | 33.7 | 32 | 26.9 | 25 | 38 | 38 |

| 25×15 | 1×1/2 | 33.7 | 32 | 21.3 | 18 | 38 | 38 |

| 32×32 | 1.1/4×1.1/4 | 42.4 | 38 | 42.4 | 38 | 48 | 48 |

| 32×25 | 1.1/4×1 | 42.4 | 38 | 33.7 | 32 | 48 | 48 |

| 32×20 | 1.1/4×3/4 | 42.4 | 38 | 26.9 | 25 | 48 | 48 |

| 32×15 | 1.1/4×1/2 | 42.4 | 38 | 21.3 | 18 | 48 | 48 |

| 40×40 | 1.1/2×1.1/2 | 48.3 | 45 | 48.3 | 45 | 57 | 57 |

| 40×32 | 1.1/2×1.1/4 | 48.3 | 45 | 42.4 | 38 | 57 | 57 |

| 40×25 | 1.1/2×1 | 48.3 | 45 | 33.7 | 32 | 57 | 57 |

| 40×20 | 1.1/2×3/4 | 48.3 | 45 | 26.9 | 25 | 57 | 57 |

| 40×15 | 1.1/2×1/2 | 48.3 | 45 | 21.3 | 18 | 57 | 57 |

| 50×50 | 2×2 | 60.3 | 57 | 60.3 | 57 | 64 | 64 |

| 50×40 | 2×1.1/2 | 60.3 | 57 | 48.3 | 45 | 64 | 60 |

| 50×32 | 2×1.1/4 | 60.3 | 57 | 42.4 | 38 | 64 | 57 |

| 50×25 | 2×1 | 60.3 | 57 | 33.7 | 32 | 64 | 51 |

| 50×20 | 2×3/4 | 60.3 | 57 | 26.9 | 25 | 64 | 44 |

GENERAL NOTES: All dimensions are in millimeters.

(a). Outlet dimension M for NPS 26(DN 650) and large is recommended but not required.

(a). Outlet dimension M for NPS 26(DN 650) and large is recommended but not required.

(b). Dimensions applicable to crosses NPS 24(DN 600) and smaller.

Pipe Cross: Pipe Cross makes 90° branch from the main run of pipe.

Applications of pipe cross:

Pipe cross are widely used in various commercial and industrial applications. Industrial applications include: Chemical processing, Petroleum, Pulp/paper, Refining, Textile, Waste treatment, Marine, Utilities/power generation, Industrial equipment, Automotive, Gas compression and distribution industries.

Pipe cross are also recommended for industrial plant fluid power systems.

Pipe cross are widely used in various commercial and industrial applications. Industrial applications include: Chemical processing, Petroleum, Pulp/paper, Refining, Textile, Waste treatment, Marine, Utilities/power generation, Industrial equipment, Automotive, Gas compression and distribution industries.

Pipe cross are also recommended for industrial plant fluid power systems.

If any inquiry, please feel free to contact by email sales@yaang.com

Related products:More>>

|  |