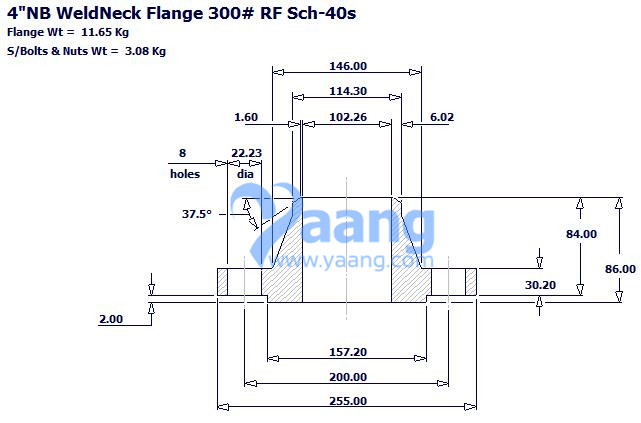

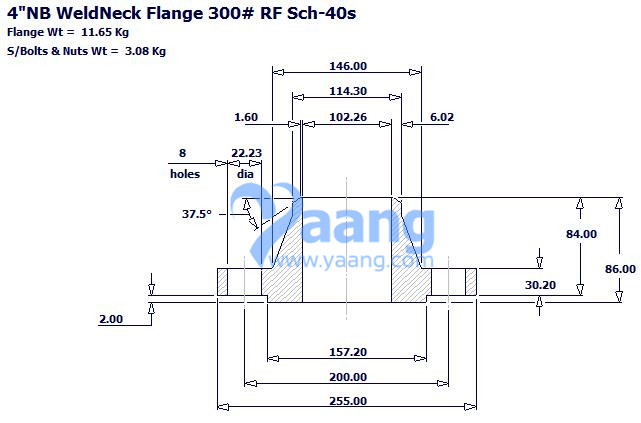

SA182 F317L WNRF Flange 4 Inch SCH40S CL300

SA182 F317L WNRF Flange

1. Material: Stainless steel F317L

2. Size: 4" (DN100)

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Size: 4" (DN100)

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Standard or Nonstandard: Standard

- Material: Stainless Steel F317L, etc

- Technics: Forging

- Type: 317L WNRF Flange

- Shape: Round

- Standard: ASME B16.5

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 15 days after receiving the deposit |

Specifications

1. Material: Stainless steel F317L

2. Size: 4" (DN100)

3. Standard: ASME B16.5

4. Type: F317L WNRF Flange

5. Pressure: 300#

China Flange Manufacturer Yaang supplies SA182 F317L WNRF Flange, 4 Inch, SCH40S, CL300.

China Flange Manufacturer Yaang supplies SA182 F317L WNRF Flange, 4 Inch, SCH40S, CL300.

The chemical composition of grade 317L stainless steel

Element Content (%) Iron, Fe Balance Chromium, Cr 18-20 Nickel, Ni 11-15 Molybdenum, Mo 3-4 Manganese, Mn 2 Silicon, Si 1 Phosphorous, P 0.045 Carbon, C 0.03 Sulfur, S 0.03

The chemical composition of grade 317L stainless steel

| Element | Content (%) |

|---|---|

| Iron, Fe | Balance |

| Chromium, Cr | 18-20 |

| Nickel, Ni | 11-15 |

| Molybdenum, Mo | 3-4 |

| Manganese, Mn | 2 |

| Silicon, Si | 1 |

| Phosphorous, P | 0.045 |

| Carbon, C | 0.03 |

| Sulfur, S | 0.03 |

The mechanical properties of grade 317L stainless steel

Properties Metric Imperial Tensile strength 595 MPa 86300 psi Yield strength 260 MPa 37700 psi Modulus of elasticity 200 GPa 29000 ksi Poisson's ratio 0.27-0.30 0.27-0.30 Elongation at break (in 50 mm) 55% 55% Hardness, Rockwell B 85 85

The mechanical properties of grade 317L stainless steel

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 595 MPa | 86300 psi |

| Yield strength | 260 MPa | 37700 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 55% | 55% |

| Hardness, Rockwell B | 85 | 85 |

| SA182 F317L WNRF Flange 4 Inch SCH40S CL300 | ||

| 1 | Material: |

Stainless Steel: such as 304, 304L, 316, 316L, 321 ,

310S, 904L, S31803, F51 and so on.

|

| 2 | Standard: | GB, JIS, BS, DIN, ANSI and Non standard |

| 3 | ANSI Class: | 15, 030, 040, 060, 090 |

| 4 | Size: | 1/2" - 24" |

| 5 | Type: |

Slip-on flanges, Blind flanges, Lap joint flanges,

Welding neck flanges,Plate flange,

Socket welding flanges and Treaded flanges

|

| 6 | Pressure ratings: |

Class: 150 300 400 600 900 1500 and 2500

PN: 6 10 16 25 40 64 and 160 , 5K - 40K and so on

|

| 7 | Sealing surface: | FF ,RF, LJ, FM , R.T.J , R.J and so on . |

| 8 | Production process: | raw material-cutting-heating-forging-heat treatment-maching-inspection. |

| 15 | Application: |

petroleum, chemical, power, gas, water, linepipe, heat exchanger,

shipbuilding, construction, etc.

|

| 16 | Tolerance: | not less than +_8% of normal wall thickness. |

PT (Penetrant Testing)

Penetrant Testing, which is called PT, is the earliest nondestructive testing method for the application of Nondestructive Testing. Because of its simple and easy operation, it is widely used in all fields of modern industry.

The main application of osmosis detection is to check the surface openings of metal (stainless steel, aluminum alloy, magnesium alloy, copper alloy, heat-resistant alloy, etc.) and non metal (plastic, ceramic, etc.), such as surface cracks.

In the process of manufacturing and operation of industrial products (pipe fittings, flanges, steel pipes), surface cracks may be produced on the surface of a few microns on the surface. Fracture mechanics research shows that these micro cracks are the source of crack in equipment under bad working conditions.

Weld neck flange is a type of pipe flange that incorporates a cast-in neck that is welded to the pipe. Unlike a plain flange that is slipped over the pipe prior to being welded into place, a weld neck flange has a spout-like neck that is beveled to match up to the pipe. Once the pipe is beveled to match the weld neck flange, a perfect V shape is created in which a butt weld is placed to connect the two components.

APPLICATIONS :

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|