ASME B16.5 Alloy 625 Swivel Ring Flange RTJ 16 Inch

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Size: 16" (DN400)

- Material: Inconel 625 (UNS N06625)

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Standard or Nonstandard: Non-standard

- Technics: Forged

- Connection: Welding

- Shape: Round

- Standard: ASME B16.5, etc

- Type: Swivel Ring Flange

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

ASME B16.5 Alloy 625 Swivel Ring Flange

1. Material: Inconel 625 (UNS N06625)

2. Size: 16" (DN400), WT:12.7

3. Connection Face: RF / RTJ

4. Standard: ASME B16.5, B16.47 and API 17D, etc

5. Pressure Rating: Class 600

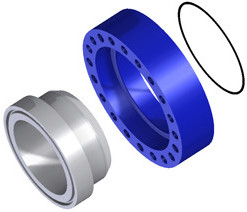

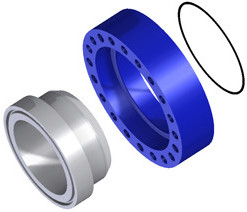

A swivel ring flange (SRF) is a two piece constructed flange used extensively for offshore pipelines and offshore industry applications. A swivel ring flange has a heavy forged welding hub that is fixed to a forged ring that can be rotated to serve as a mating flange to a weld neck or another flange. In a swivel ring flange, the rotating ring is held on by the welding hub that is in turn secured by a retaining ring.

China Swivel Ring Flange Manufacturer Yaang offers ASME B16.5 Alloy 625 Swivel Ring Flange, RTJ, 16 Inch.

1. Material: Inconel 625 (UNS N06625)

2. Size: 16" (DN400), WT:12.7

3. Connection Face: RF / RTJ

4. Standard: ASME B16.5, B16.47 and API 17D, etc

5. Pressure Rating: Class 600

A swivel ring flange (SRF) is a two piece constructed flange used extensively for offshore pipelines and offshore industry applications. A swivel ring flange has a heavy forged welding hub that is fixed to a forged ring that can be rotated to serve as a mating flange to a weld neck or another flange. In a swivel ring flange, the rotating ring is held on by the welding hub that is in turn secured by a retaining ring.

China Swivel Ring Flange Manufacturer Yaang offers ASME B16.5 Alloy 625 Swivel Ring Flange, RTJ, 16 Inch.

Composition ranges for Inconel 625 (UNS N06625)

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

|---|---|---|---|---|---|---|---|

| 20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S | |||

|---|---|---|---|---|---|---|---|

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

A swivel ring flange is also known as a swivel flange.

Swivel ring flanges are favored because they do not cause any problems in the alignment of bolt holes during sub-sea flange installation. Swivel ring flanges are available in various metals and specifications, including class 150 to class 2500 specifications and from 1 inch to 60 inches in diameter. These flanges are readily mated to any standard welded neck flange and are very similar to ASME / ANSI B 16.5 and MSS-SP44 standard flanges.

Swivel ring flanges are constructed using a specific grade of carbon steel or stainless steel having ASTM A105 specifications with a minimum yield of 42,000 psi pressure. Some extra thickness is provided at the welding end. These flanges are also manufactured using superior grade materials such as A694 or A707.

The SRF utilizes a spring steel retainer ring to capture the rotating flange component of the connector, thus eliminating welded retainers and permitting the removal of the retainer ring. This also makes it possible to clean and lubricate the swivel ring interface between the hub and flange after fabrication and coating to ensure easy rotation during installation

Stock inventory sizes are available from 2″ to 24″ for immediate delivery. Additional sizes available upon request.

A swivel ring flange is also known as a swivel flange.

Swivel ring flanges are favored because they do not cause any problems in the alignment of bolt holes during sub-sea flange installation. Swivel ring flanges are available in various metals and specifications, including class 150 to class 2500 specifications and from 1 inch to 60 inches in diameter. These flanges are readily mated to any standard welded neck flange and are very similar to ASME / ANSI B 16.5 and MSS-SP44 standard flanges.

Swivel ring flanges are constructed using a specific grade of carbon steel or stainless steel having ASTM A105 specifications with a minimum yield of 42,000 psi pressure. Some extra thickness is provided at the welding end. These flanges are also manufactured using superior grade materials such as A694 or A707.

The SRF utilizes a spring steel retainer ring to capture the rotating flange component of the connector, thus eliminating welded retainers and permitting the removal of the retainer ring. This also makes it possible to clean and lubricate the swivel ring interface between the hub and flange after fabrication and coating to ensure easy rotation during installation

Stock inventory sizes are available from 2″ to 24″ for immediate delivery. Additional sizes available upon request.

A swivel ring flange is also known as a swivel flange.

Swivel ring flanges are favored because they do not cause any problems in the alignment of bolt holes during sub-sea flange installation. Swivel ring flanges are available in various metals and specifications, including class 150 to class 2500 specifications and from 1 inch to 60 inches in diameter. These flanges are readily mated to any standard welded neck flange and are very similar to ASME / ANSI B 16.5 and MSS-SP44 standard flanges.

Swivel ring flanges are constructed using a specific grade of carbon steel or stainless steel having ASTM A105 specifications with a minimum yield of 42,000 psi pressure. Some extra thickness is provided at the welding end. These flanges are also manufactured using superior grade materials such as A694 or A707.

The SRF utilizes a spring steel retainer ring to capture the rotating flange component of the connector, thus eliminating welded retainers and permitting the removal of the retainer ring. This also makes it possible to clean and lubricate the swivel ring interface between the hub and flange after fabrication and coating to ensure easy rotation during installation

Stock inventory sizes are available from 2″ to 24″ for immediate delivery. Additional sizes available upon request.

Swivel-ring flanges are used extensively in the offshore industries and for subsea applications. Yaang can manufacture and supply swivel-ring flanges to exacting standards and they can be designed to suit any pressure rating. (The pressure-temperature ratings and basic dimensions (OD - bolt circle - facing - number and size of bolts) of Swivel Ring Flanges, in Class 150 through Class 2500, are identical to ASME/ANSI B16.5 and MSS-SP44 Flanges and will readily mate to a standard weld neck flange. Ring type joints (RTJ), raised face, flat face and other facings are furnished as required. Sizes up through 60” including flanges to mate to ASME B16.47 dimensions are available.)

One of the main features of a swivel-ring flange is that it allows a 360 degree rotation of an outer ring around a hub and this enables easy alignment of bolt holes when attaching to a standard flange. This is particularly important for subsea applications when there is only one diver available to align and set up the flange connection.

At YAANG we can design swivel-ring flanges for a variety of size and pressure ratings; standard specifications being API 6A, ASME B16.5 and MSS SP-44. We can also custom-design swivel-ring flanges based on your specific requirements.

Swivel-ring flanges consist of an inner hub that is welded in place and an outer flange ring that is able to rotate freely. This makes swivel-ring flanges easier to install in difficult situations such as subsea applications. Swivel-ring flanges can reduce cost and increase safety in subsea scenarios and that’s why they are commonly used in the offshore industries.

Dimensional standards:

- ANSI B16.5

- 47 Series A and B16.47 Series B

- API 6A

- API 17D

- BS EN 1092-1

- BS 4504

- BS 10

- Din

- JIS

- Norsok L-005

- Bespoke to customer drawings / design.

Standard grades:

- ASTMÂ / ASME A182 / SA182 F51 / F60 / 31803/ 1.4462

- ASTM / ASMEÂ A182 / SA182 F53/F55 / 32750 / 32760

- ASTMÂ / ASME A182 / SA182Â F44 / 31254

- ASTM / ASME / B564 / SB564 UNS NO6625 / Alloy 625 / Inconel® 625

- ASTM / ASME / B564 / SB564 UNS NO8800 / Alloy 800 / Incoloy® 800

- ASTM / ASME / B564 / SB564 UNS NO8810 / Alloy 800H / Incoloy® 800H

- ASTM / ASME / B564 / SB564 UNS NO8811 / Alloy 800HT / Incoloy® 800HT

- ASTM / ASME / B564 / SB564 UNS NO6600 / Alloy 600 / Inconel® 600

- ASTM / ASME / B564 / SB564 UNS NO6601 / Alloy 601 / Inconel® 601

- ASTM / ASME / B564 / SB564 UNS NO8020 / Alloy 20 / Carpenter® 20

- ASTM / ASME / B564 / SB564 UNS NO2200 / Alloy 200

- ASTM / ASME / B564 / SB564 UNS NO2201 / Alloy 201

- ASTM / ASME / B564 / SB564 UNS NO6625 / Alloy 400 / Monel® 400

- ASTM / ASME / B564 / SB564 UNS NO7718 / Alloy 718

- ASTM / ASME / B564 / SB564 UNS NO8825 / Alloy 825 / Incoloy® 825

- ASTM / ASME / B564 / SB564 UNS NO10276 / Alloy C276 / Hastelloy®C276

- ASTM / ASME / B564 / SB564 UNS NO6022 / Alloy 22 / Hastelloy® 22

- ASTM / ASME / B564 / SB564 UNS NO10675 / Alloy B3 / Hastelloy® B3

- ASTM / ASME / A182 / SA182 UNS NO8028 / Alloy 28 / Sanicro®28

- ASTM / ASME / B564 / SB564 UNS NO5500 / Alloy K500 / Monel® K500

- ASTM / ASME / A182 / SA182 F304 / F304L / F304H

- ASTM / ASME / A182 / SA182 F316 / F316L / F316H

- ASTM / ASME / A182 / SA182 F321 / F321H

Standard facings:

- Raised face

- Ring-type joint

- Flat face

- Male/female

- Tongue/groove

Swivel- Ring Flange Features

All of our swivel-ring flanges meet the API 6H specifications and are designed in full accordance with the latest ASME Pressure Vessel Code. Features include:

- The ability to supply for any size and pressure rating

- 360 degree rotation to enable easy alignment

- Availability for any flange specifications including MSS SP44, ASME B16.5 and API 6A

Where can we find the high quality ASME B16.5 Alloy 625 Swivel Ring Flange RTJ 16 Inch.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

APPLICATIONS:

1. Pipeline repair operations – shallow water, diver assist

2. Pipeline new construction for tie-in point – shallow water, diver assist

Key Features:

Where can we find the high quality ASME B16.5 Alloy 625 Swivel Ring Flange RTJ 16 Inch.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

APPLICATIONS:

1. Pipeline repair operations – shallow water, diver assist

2. Pipeline new construction for tie-in point – shallow water, diver assist

Key Features:

- Simple design facilitates bolt-hole alignment.

- Spring retainer eliminates welded retainer components.

- Removable retainer allows for cleaning and lubricating of the hub-to-flange interface.

- Thicker flange ensures ability to handle higher-stress loads, which some brands fail to meet.

- Fully compliant with ASME Section VIII.

Swivel-ring flanges are used extensively in the offshore industries and for subsea applications. Yaang can manufacture and supply swivel-ring flanges to exacting standards and they can be designed to suit any pressure rating. (The pressure-temperature ratings and basic dimensions (OD - bolt circle - facing - number and size of bolts) of Swivel Ring Flanges, in Class 150 through Class 2500, are identical to ASME/ANSI B16.5 and MSS-SP44 Flanges and will readily mate to a standard weld neck flange. Ring type joints (RTJ), raised face, flat face and other facings are furnished as required. Sizes up through 60” including flanges to mate to ASME B16.47 dimensions are available.)

One of the main features of a swivel-ring flange is that it allows a 360 degree rotation of an outer ring around a hub and this enables easy alignment of bolt holes when attaching to a standard flange. This is particularly important for subsea applications when there is only one diver available to align and set up the flange connection.

At YAANG we can design swivel-ring flanges for a variety of size and pressure ratings; standard specifications being API 6A, ASME B16.5 and MSS SP-44. We can also custom-design swivel-ring flanges based on your specific requirements.

Swivel-ring flanges consist of an inner hub that is welded in place and an outer flange ring that is able to rotate freely. This makes swivel-ring flanges easier to install in difficult situations such as subsea applications. Swivel-ring flanges can reduce cost and increase safety in subsea scenarios and that’s why they are commonly used in the offshore industries.

Dimensional standards:

- ANSI B16.5

- 47 Series A and B16.47 Series B

- API 6A

- API 17D

- BS EN 1092-1

- BS 4504

- BS 10

- Din

- JIS

- Norsok L-005

- Bespoke to customer drawings / design.

Standard grades:

- ASTMÂ / ASME A182 / SA182 F51 / F60 / 31803/ 1.4462

- ASTM / ASMEÂ A182 / SA182 F53/F55 / 32750 / 32760

- ASTMÂ / ASME A182 / SA182Â F44 / 31254

- ASTM / ASME / B564 / SB564 UNS NO6625 / Alloy 625 / Inconel® 625

- ASTM / ASME / B564 / SB564 UNS NO8800 / Alloy 800 / Incoloy® 800

- ASTM / ASME / B564 / SB564 UNS NO8810 / Alloy 800H / Incoloy® 800H

- ASTM / ASME / B564 / SB564 UNS NO8811 / Alloy 800HT / Incoloy® 800HT

- ASTM / ASME / B564 / SB564 UNS NO6600 / Alloy 600 / Inconel® 600

- ASTM / ASME / B564 / SB564 UNS NO6601 / Alloy 601 / Inconel® 601

- ASTM / ASME / B564 / SB564 UNS NO8020 / Alloy 20 / Carpenter® 20

- ASTM / ASME / B564 / SB564 UNS NO2200 / Alloy 200

- ASTM / ASME / B564 / SB564 UNS NO2201 / Alloy 201

- ASTM / ASME / B564 / SB564 UNS NO6625 / Alloy 400 / Monel® 400

- ASTM / ASME / B564 / SB564 UNS NO7718 / Alloy 718

- ASTM / ASME / B564 / SB564 UNS NO8825 / Alloy 825 / Incoloy® 825

- ASTM / ASME / B564 / SB564 UNS NO10276 / Alloy C276 / Hastelloy®C276

- ASTM / ASME / B564 / SB564 UNS NO6022 / Alloy 22 / Hastelloy® 22

- ASTM / ASME / B564 / SB564 UNS NO10675 / Alloy B3 / Hastelloy® B3

- ASTM / ASME / A182 / SA182 UNS NO8028 / Alloy 28 / Sanicro®28

- ASTM / ASME / B564 / SB564 UNS NO5500 / Alloy K500 / Monel® K500

- ASTM / ASME / A182 / SA182 F304 / F304L / F304H

- ASTM / ASME / A182 / SA182 F316 / F316L / F316H

- ASTM / ASME / A182 / SA182 F321 / F321H

Standard facings:

- Raised face

- Ring-type joint

- Flat face

- Male/female

- Tongue/groove

Swivel- Ring Flange Features

All of our swivel-ring flanges meet the API 6H specifications and are designed in full accordance with the latest ASME Pressure Vessel Code. Features include:

- The ability to supply for any size and pressure rating

- 360 degree rotation to enable easy alignment

- Availability for any flange specifications including MSS SP44, ASME B16.5 and API 6A

Where can we find the high quality ASME B16.5 Alloy 625 Swivel Ring Flange RTJ 16 Inch.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

APPLICATIONS:

1. Pipeline repair operations – shallow water, diver assist

2. Pipeline new construction for tie-in point – shallow water, diver assist

Key Features:

- Simple design facilitates bolt-hole alignment.

- Spring retainer eliminates welded retainer components.

- Removable retainer allows for cleaning and lubricating of the hub-to-flange interface.

- Thicker flange ensures ability to handle higher-stress loads, which some brands fail to meet.

- Fully compliant with ASME Section VIII.

Related products:More>>

|