ANSI B16.5 A182 F304 SORF Flange 3 Inch CL150

ANSI B16.5 A182 F304 SORF Flange

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Size: 3" (DN80)

- Material: 304, etc

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Standard or Nonstandard: Standard

- Technics: Forged

- Connection: Welding

- Shape: Round

- Standard: ASME B16.5

- Type: 304 SORF Flange

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

ANSI B16.5 A182 F304 SORF Flange1. Material: 304

2. Size: 3" (DN80)

3. Standard: ANSI B16.5

4. Pressure: 150#

2. Size: 3" (DN80)

3. Standard: ANSI B16.5

4. Pressure: 150#

Composition ranges for 304L grade stainless steel

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

304

min.

max.

-

0.08

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

0.10

304L

min.

max.

-

0.030

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

12.0

-

0.10

304H

min.

max.

0.04

0.10

-

2.0

-

0.75

-0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

Composition ranges for 304L grade stainless steel

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

| |

304

|

min.

max.

|

-

0.08

|

-

2.0

|

-

0.75

|

-

0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

10.5

|

-

0.10

|

304L

|

min.

max.

|

-

0.030

|

-

2.0

|

-

0.75

|

-

0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

12.0

|

-

0.10

|

304H

|

min.

max.

|

0.04

0.10

|

-

2.0

|

-

0.75

|

-0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

10.5

|

-

|

Mechanical properties of 304L grade stainless steel

Grade

Tensile Strength (MPa) min

Yield Strength 0.2% Proof (MPa) min

Elongation (% in 50mm) min

Hardness

Rockwell B (HR B) max

Brinell (HB) max

304

515

205

40

92

201

304L

485

170

40

92

201

304H

515

205

40

92

201

304H also has a requirement for a grain size of ASTM No 7 or coarser.

Grade

|

Tensile Strength (MPa) min

|

Yield Strength 0.2% Proof (MPa) min

|

Elongation (% in 50mm) min

|

Hardness

| |

Rockwell B (HR B) max

|

Brinell (HB) max

| ||||

304

|

515

|

205

|

40

|

92

|

201

|

304L

|

485

|

170

|

40

|

92

|

201

|

304H

|

515

|

205

|

40

|

92

|

201

|

304H also has a requirement for a grain size of ASTM No 7 or coarser.

| |||||

Physical properties of 304L grade stainless steel in the annealed condition

Grade

Density (kg/m3)

Elastic Modulus (GPa)

Mean Coefficient of Thermal Expansion (μm/m/°C)

Thermal Conductivity (W/m.K)

Specific Heat 0-100°C (J/kg.K)

Electrical Resistivity (nΩ.m)

0-100°C

0-315°C

0-538°C

at 100°C

at 500°C

304/L/H

8000

193

17.2

17.8

18.4

16.2

21.5

500

720

Grade

|

Density (kg/m3)

|

Elastic Modulus (GPa)

|

Mean Coefficient of Thermal Expansion (μm/m/°C)

|

Thermal Conductivity (W/m.K)

|

Specific Heat 0-100°C (J/kg.K)

|

Electrical Resistivity (nΩ.m)

| |||

0-100°C

|

0-315°C

|

0-538°C

|

at 100°C

|

at 500°C

| |||||

304/L/H

|

8000

|

193

|

17.2

|

17.8

|

18.4

|

16.2

|

21.5

|

500

|

720

|

Grade specifications for 304L grade stainless steel

Grade

UNS No

Old British

Euronorm

Swedish SS

Japanese JIS

BS

En

No

Name

304

S30400

304S31

58E

1.4301

X5CrNi18-10

2332

SUS 304

304L

S30403

304S11

-

1.4306

X2CrNi19-11

2352

SUS 304L

304H

S30409

304S51

-

1.4948

X6CrNi18-11

-

-

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

Grade

|

UNS No

|

Old British

|

Euronorm

|

Swedish SS

|

Japanese JIS

| ||

BS

|

En

|

No

|

Name

| ||||

304

|

S30400

|

304S31

|

58E

|

1.4301

|

X5CrNi18-10

|

2332

|

SUS 304

|

304L

|

S30403

|

304S11

|

-

|

1.4306

|

X2CrNi19-11

|

2352

|

SUS 304L

|

304H

|

S30409

|

304S51

|

-

|

1.4948

|

X6CrNi18-11

|

-

|

-

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

| |||||||

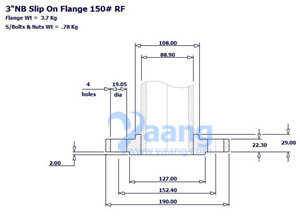

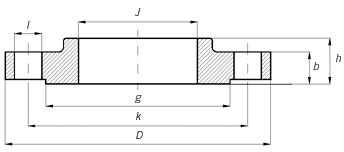

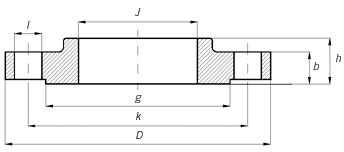

Flange Dimensions & Approximate Masses

ANSI, ASME, ASA, B16.5 150lb/sq.in. SLIP ON FLANGE RF / FF ø D b g m J h k Holes l Kg. 1/2" 88,9 11,1 34,9 30,2 22,3 15,9 60,3 4 15,9 0,400 3/4" 98,4 12,7 42,9 38,1 27,7 15,9 69,8 4 15,9 0,700 1" 107,9 14,3 50,8 49,2 34,5 17,5 79,4 4 15,9 0,800 1 1/4" 117,5 15,9 63,5 58,8 43,2 20,6 88,9 4 15,9 1,100 1 1/2" 127,0 17,5 73,0 65,1 49,5 22,2 98,4 4 15,9 1,400 2" 152,4 19,0 92,1 77,8 62,0 25,4 120,6 4 19,0 2,200 2 1/2" 177,8 22,2 104,8 90,5 74,7 28,6 139,7 4 19,0 3,600 3" 190,5 23,8 127,0 107,9 90,7 30,2 152,4 4 19,0 4,100 3 1/2" 215,9 23,8 139,7 122,2 103,4 31,7 177,8 8 19,0 5,200 4" 228,6 23,8 157,2 134,9 116,1 33,3 190,5 8 19,0 5,600 5" 254,0 23,8 185,7 163,6 143,8 36,5 215,9 8 22,2 6,300 6" 279,4 25,4 215,9 192,1 170,7 39,7 241,3 8 22,2 7,500 8" 342,9 28,6 269,9 246,1 221,5 44,4 298,4 8 22,2 12,600 10" 406,4 30,2 323,8 304,8 276,3 49,2 361,9 12 25,4 18,500 12" 482,6 31,7 381,0 365,1 327,1 55,6 431,8 12 25,5 28,000 14" 533,4 34,9 412,7 400,0 359,1 57,1 476,2 12 28,6 36,000 16" 596,9 36,5 469,9 457,2 410,5 63,5 539,7 16 28,6 46,000 18" 635,0 39,7 533,4 504,8 461,8 68,3 577,8 16 31,7 50,000 20" 698,5 42,9 584,2 558,8 513,1 73,0 635,0 20 31,7 64,000 22" 749,3 46,0 641,2 609,6 564,4 79,4 692,1 20 34,9 72,000 24" 812,8 47,6 692,1 663,6 615,9 82,5 749,3 20 34,9 89,000

NOTE:

1. Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

APPLICATIONS Of ANSI B16.5 B16.5 A182 304L SORF Flange:

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Slip on flanges are slipped over the pipe and welded (usually both inside and outside) to provide strength and prevent leakage. Slip on Flanges are at the low cost end of the scale, and do not require high accuracy when cutting the pipe to length. These slip on can sometimes have a boss or hub, and can be made with a bore to suit either pipe or tube.

Where can we find the high quality ANSI B16.5 A182 F304 SORF Flange 3 Inch CL150.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

| Flange Dimensions & Approximate Masses |

| ANSI, ASME, ASA, B16.5 150lb/sq.in. SLIP ON FLANGE RF / FF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2" | 88,9 | 11,1 | 34,9 | 30,2 | 22,3 | 15,9 | 60,3 | 4 | 15,9 | 0,400 |

| 3/4" | 98,4 | 12,7 | 42,9 | 38,1 | 27,7 | 15,9 | 69,8 | 4 | 15,9 | 0,700 |

| 1" | 107,9 | 14,3 | 50,8 | 49,2 | 34,5 | 17,5 | 79,4 | 4 | 15,9 | 0,800 |

| 1 1/4" | 117,5 | 15,9 | 63,5 | 58,8 | 43,2 | 20,6 | 88,9 | 4 | 15,9 | 1,100 |

| 1 1/2" | 127,0 | 17,5 | 73,0 | 65,1 | 49,5 | 22,2 | 98,4 | 4 | 15,9 | 1,400 |

| 2" | 152,4 | 19,0 | 92,1 | 77,8 | 62,0 | 25,4 | 120,6 | 4 | 19,0 | 2,200 |

| 2 1/2" | 177,8 | 22,2 | 104,8 | 90,5 | 74,7 | 28,6 | 139,7 | 4 | 19,0 | 3,600 |

| 3" | 190,5 | 23,8 | 127,0 | 107,9 | 90,7 | 30,2 | 152,4 | 4 | 19,0 | 4,100 |

| 3 1/2" | 215,9 | 23,8 | 139,7 | 122,2 | 103,4 | 31,7 | 177,8 | 8 | 19,0 | 5,200 |

| 4" | 228,6 | 23,8 | 157,2 | 134,9 | 116,1 | 33,3 | 190,5 | 8 | 19,0 | 5,600 |

| 5" | 254,0 | 23,8 | 185,7 | 163,6 | 143,8 | 36,5 | 215,9 | 8 | 22,2 | 6,300 |

| 6" | 279,4 | 25,4 | 215,9 | 192,1 | 170,7 | 39,7 | 241,3 | 8 | 22,2 | 7,500 |

| 8" | 342,9 | 28,6 | 269,9 | 246,1 | 221,5 | 44,4 | 298,4 | 8 | 22,2 | 12,600 |

| 10" | 406,4 | 30,2 | 323,8 | 304,8 | 276,3 | 49,2 | 361,9 | 12 | 25,4 | 18,500 |

| 12" | 482,6 | 31,7 | 381,0 | 365,1 | 327,1 | 55,6 | 431,8 | 12 | 25,5 | 28,000 |

| 14" | 533,4 | 34,9 | 412,7 | 400,0 | 359,1 | 57,1 | 476,2 | 12 | 28,6 | 36,000 |

| 16" | 596,9 | 36,5 | 469,9 | 457,2 | 410,5 | 63,5 | 539,7 | 16 | 28,6 | 46,000 |

| 18" | 635,0 | 39,7 | 533,4 | 504,8 | 461,8 | 68,3 | 577,8 | 16 | 31,7 | 50,000 |

| 20" | 698,5 | 42,9 | 584,2 | 558,8 | 513,1 | 73,0 | 635,0 | 20 | 31,7 | 64,000 |

| 22" | 749,3 | 46,0 | 641,2 | 609,6 | 564,4 | 79,4 | 692,1 | 20 | 34,9 | 72,000 |

| 24" | 812,8 | 47,6 | 692,1 | 663,6 | 615,9 | 82,5 | 749,3 | 20 | 34,9 | 89,000 |

NOTE:

1. Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3). 2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees. 3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub. 4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C). 5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option. |

APPLICATIONS Of ANSI B16.5 B16.5 A182 304L SORF Flange:

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Slip on flanges are slipped over the pipe and welded (usually both inside and outside) to provide strength and prevent leakage. Slip on Flanges are at the low cost end of the scale, and do not require high accuracy when cutting the pipe to length. These slip on can sometimes have a boss or hub, and can be made with a bore to suit either pipe or tube.

Where can we find the high quality ANSI B16.5 A182 F304 SORF Flange 3 Inch CL150.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|