AS 2129 T/E 316L Threaded Bossed Flange FF 1-1/4 Inch

AS 2129 T/E 316L Threaded Bossed Flange Flat Face

Quick Details

| Material: |

316L

| Size: |

1 1/4" (DN32)

| Type: | Threaded Bossed Flange |

| Place of Origin: |

Zhejiang, China (Mainland)

| Connection: |

Welding

| Brand Name: |

Yaang

|

| Standard: |

AS 2129

| Shape: |

Round

| Standard or Nonstandard: |

Standard

|

| Technics: |

Forged

|

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

AS 2129 T/E 316L Threaded Bossed Flange Flat Face

1. Material: 316L

2. Size: 1 1/4" (DN32)

3. Standard: AS 2129

4. Type: Table E

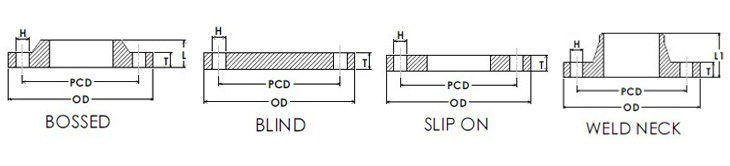

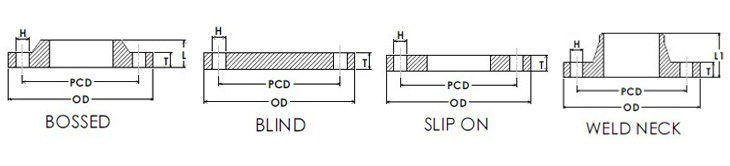

Threaded bossed flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications.

Threaded bossed flanges are also known as screwed bossed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe.

This type of joint connection is speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water.

Threaded (Screwed) flange is similar to the Slip-On flange, but the bore is threaded. Its chief merit is that it can be assembled withour welding, explaining its use in low pressure services at ordinary atmospheric temperatures, and in highly explosive areas where welding create a hazard.

In Australia the BS and AS flange standards are essentially the same but have been metricated. Consequently metric sizes are stated as ‘DN’ (Nominal Diameter) in mm. Equivalent imperial sizing is rounded to the nearest multiple of 25mm (for 2” and over) as below. However the actual dimensions and bore sizes have not changed. ‘NB’ (Nominal Bore) is also sometimes used when referring to valve sizes.

AS2129 originates from BS10 and has been metricated. In some cases slightly larger bolt holes provide better clearance as metric bolts are specified in lieu of UNC bolts used by BS10. AS4087 is an update of AS2129, however AS2129 is still widely used so it has not been deleted as a standard, however, it now only covers AS table D, E to H.

China Bossed Flange Manufacturer Yaang supplies AS 2129 T/E 316L Threaded Bossed Flange FF, 1-1/4 Inch.

2. Size: 1 1/4" (DN32)

3. Standard: AS 2129

4. Type: Table E

Threaded bossed flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications.

Threaded bossed flanges are also known as screwed bossed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe.

This type of joint connection is speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water.

Threaded (Screwed) flange is similar to the Slip-On flange, but the bore is threaded. Its chief merit is that it can be assembled withour welding, explaining its use in low pressure services at ordinary atmospheric temperatures, and in highly explosive areas where welding create a hazard.

In Australia the BS and AS flange standards are essentially the same but have been metricated. Consequently metric sizes are stated as ‘DN’ (Nominal Diameter) in mm. Equivalent imperial sizing is rounded to the nearest multiple of 25mm (for 2” and over) as below. However the actual dimensions and bore sizes have not changed. ‘NB’ (Nominal Bore) is also sometimes used when referring to valve sizes.

AS2129 originates from BS10 and has been metricated. In some cases slightly larger bolt holes provide better clearance as metric bolts are specified in lieu of UNC bolts used by BS10. AS4087 is an update of AS2129, however AS2129 is still widely used so it has not been deleted as a standard, however, it now only covers AS table D, E to H.

China Bossed Flange Manufacturer Yaang supplies AS 2129 T/E 316L Threaded Bossed Flange FF, 1-1/4 Inch.

Composition ranges for 316L grade of stainless steels

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | Min | - | - | - | 0 | - | 16.0 | 2.00 | 10.0 | - |

| Max | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

| Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316H | Min | 0.04 | 0.04 | 0 | - | - | 16.0 | 2.00 | 10.0 | - |

| max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | - |

Standard AS 2129 Table "E" Flange

Standard AS 2129 Table "E" Flange

TABLE E

LENGTH THROUGH HUB

DRILLING DATA

TABLE E

NOMINAL

PIPE SIZE

FLANGE

OUTSIDE

DIAMETER

THICKNESS

OF

FLANGE

(Refer Note.1)

BOSSED

SOW

WELD

NECK

PITCH

CIRCLE

DIAMETER

BOLT

HOLE

DIAMETER

NUMBER

OF

BOLT

HOLES

NOMINAL

PIPE SIZE

MM

INCH

OD

T

L

L1

PCD

H

﹟

MM

INCH

15

1/2

95

6

16

28

67

14

4

15

1/2

20

3/4

100

6

17

28

73

14

4

20

3/4

25

1

115

7

18

29

83

14

4

25

1

32

1 1/4

120

8

19

33

87

14

4

32

1 1/4

40

1 1/2

135

9

22

38

98

14

4

40

1 1/2

50

2

150

10

23

39

114

18

4

50

2

65

2 1/2

165

10

26

42

127

18

4

65

2 1/2

80

3

185

11

27

46

146

18

4

80

3

90

3 1/2

205

12

29

47

165

18

8

90

3 1/2

100

4

215

13

32

54

178

18

8

100

4

NOTES:

(1) The minimum flange thickness in carbon steel flanges will be 12mm.

(2) Bore sizes to suit ASME B 36.10B36.19 pipe unless otherwise specified.

(3) Flanges are generally supplied flat faced.

Standard AS 2129 Table "E" Flange

TABLE E

|

LENGTH THROUGH HUB

|

DRILLING DATA

|

TABLE E

| |||||||

NOMINAL

PIPE SIZE |

FLANGE

OUTSIDE DIAMETER |

THICKNESS

OF FLANGE (Refer Note.1) |

BOSSED

SOW |

WELD

NECK |

PITCH

CIRCLE DIAMETER |

BOLT

HOLE DIAMETER |

NUMBER

OF BOLT HOLES |

NOMINAL

PIPE SIZE | ||

MM

|

INCH

|

OD

|

T

|

L

|

L1

|

PCD

|

H

|

﹟

|

MM

|

INCH

|

15

|

1/2

|

95

|

6

|

16

|

28

|

67

|

14

|

4

|

15

|

1/2

|

20

|

3/4

|

100

|

6

|

17

|

28

|

73

|

14

|

4

|

20

|

3/4

|

25

|

1

|

115

|

7

|

18

|

29

|

83

|

14

|

4

|

25

|

1

|

32

|

1 1/4

|

120

|

8

|

19

|

33

|

87

|

14

|

4

|

32

|

1 1/4

|

40

|

1 1/2

|

135

|

9

|

22

|

38

|

98

|

14

|

4

|

40

|

1 1/2

|

50

|

2

|

150

|

10

|

23

|

39

|

114

|

18

|

4

|

50

|

2

|

65

|

2 1/2

|

165

|

10

|

26

|

42

|

127

|

18

|

4

|

65

|

2 1/2

|

80

|

3

|

185

|

11

|

27

|

46

|

146

|

18

|

4

|

80

|

3

|

90

|

3 1/2

|

205

|

12

|

29

|

47

|

165

|

18

|

8

|

90

|

3 1/2

|

100

|

4

|

215

|

13

|

32

|

54

|

178

|

18

|

8

|

100

|

4

|

NOTES:

(1) The minimum flange thickness in carbon steel flanges will be 12mm.

(2) Bore sizes to suit ASME B 36.10B36.19 pipe unless otherwise specified.

(3) Flanges are generally supplied flat faced.

| ||||||||||

APPLICATIONS:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Uses of threaded bossed flanges:

Threaded bossed flanges are threaded in the bore which match an external thread on the pipe. Threaded bossed flanges are used with pipes that have external threads. The benefit of these flanges is that it can be attached without welding.

Threaded bossed flanges can be fitted to pipes of various sizes without welding and this is one chief benefit for which these flanges are highly demanded.

- They can be used in extremely high pressure applications, particularly at or near atmospheric temperature, where the necessary post weld heat treatment is not possible.

- They are ideal for small diameter piping applications.

- They are economical and time saving devices.

- These threaded bossed flanges are normally designed for non-cyclic applications.

- The flanges are suitable to be used in applications where welding is hazardous.

- They can be used in highly explosive areas.

APPLICATIONS:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Uses of threaded bossed flanges:

Threaded bossed flanges are threaded in the bore which match an external thread on the pipe. Threaded bossed flanges are used with pipes that have external threads. The benefit of these flanges is that it can be attached without welding.

Threaded bossed flanges can be fitted to pipes of various sizes without welding and this is one chief benefit for which these flanges are highly demanded.

- They can be used in extremely high pressure applications, particularly at or near atmospheric temperature, where the necessary post weld heat treatment is not possible.

- They are ideal for small diameter piping applications.

- They are economical and time saving devices.

- These threaded bossed flanges are normally designed for non-cyclic applications.

- The flanges are suitable to be used in applications where welding is hazardous.

- They can be used in highly explosive areas.

316L Threaded Bossed Flange FF's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality AS 2129 T/E 316L Threaded Bossed Flange FF 1-1/4 Inch.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited is a China Blind Flange Manufacturer).

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|