ANSI B16.9 ASTM A403 WP304 Reducing Tee 1 1/4 - 1/2 Inch SCH40S

ANSI B16.9 ASTM A403 WP304 Reducing Tee's Packing & Shipping

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

| Material: |

304

| Technics: |

Forged

| Type: | Reducing Tee |

| Place of Origin: |

Zhejiang, China (Mainland)

| Model Number: |

Reducing Tee

| Brand Name: |

Yaang

|

| Connection: |

Welding, Weld

| Shape: |

Equal

| Head Code: |

Round

|

Packaging & Delivery

Packaging Detail: Plywood case or fumigation woodern case Delivery Detail: Usually 2-10 days depend on the quantity

| Packaging Detail: | Plywood case or fumigation woodern case |

| Delivery Detail: | Usually 2-10 days depend on the quantity |

Specifications

ANSI B16.9 ASTM A403 WP304 Reducing Tee 1 1/4 - 1/2 Inch SCH40S

1) Size: 1 1/4 - 1/2 Inch

2) THK: SCH40S

3) Material: 304

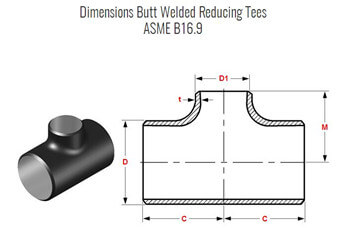

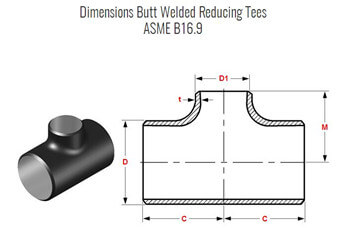

ANSI B16.9 ASTM A403 WP304 Reducing Tee, like all pipe tees, is in the shape of T with two ends of equal size and the third one slightly smaller. In other words, 304 smls reducing tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run. This type of pipe fitting can also consider size reduction from one of the run ports to the other.

China Reducing Tee Manufacturer Yaang supplies ANSI B16.9 ASTM A403 WP304 Reducing Tee, 1 1/4 - 1/2 Inch, SCH40S.

Composition ranges for 304 grade stainless steel

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

304

min.

max.

-

0.08

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

0.10

304L

min.

max.

-

0.030

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

12.0

-

0.10

304H

min.

max.

0.04

0.10

-

2.0

-

0.75

-0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

1) Size: 1 1/4 - 1/2 Inch

2) THK: SCH40S

3) Material: 304

ANSI B16.9 ASTM A403 WP304 Reducing Tee, like all pipe tees, is in the shape of T with two ends of equal size and the third one slightly smaller. In other words, 304 smls reducing tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run. This type of pipe fitting can also consider size reduction from one of the run ports to the other.

China Reducing Tee Manufacturer Yaang supplies ANSI B16.9 ASTM A403 WP304 Reducing Tee, 1 1/4 - 1/2 Inch, SCH40S.

Composition ranges for 304 grade stainless steel

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

| |

304

|

min.

max.

|

-

0.08

|

-

2.0

|

-

0.75

|

-

0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

10.5

|

-

0.10

|

304L

|

min.

max.

|

-

0.030

|

-

2.0

|

-

0.75

|

-

0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

12.0

|

-

0.10

|

304H

|

min.

max.

|

0.04

0.10

|

-

2.0

|

-

0.75

|

-0.045

|

-

0.030

|

18.0

20.0

|

-

|

8.0

10.5

|

-

|

Mechanical properties of 304 grade stainless steel

Grade

Tensile Strength (MPa) min

Yield Strength 0.2% Proof (MPa) min

Elongation (% in 50mm) min

Hardness

Rockwell B (HR B) max

Brinell (HB) max

304

515

205

40

92

201

304L

485

170

40

92

201

304H

515

205

40

92

201

304H also has a requirement for a grain size of ASTM No 7 or coarser.

Mechanical properties of 304 grade stainless steel

Grade

|

Tensile Strength (MPa) min

|

Yield Strength 0.2% Proof (MPa) min

|

Elongation (% in 50mm) min

|

Hardness

| |

Rockwell B (HR B) max

|

Brinell (HB) max

| ||||

304

|

515

|

205

|

40

|

92

|

201

|

304L

|

485

|

170

|

40

|

92

|

201

|

304H

|

515

|

205

|

40

|

92

|

201

|

304H also has a requirement for a grain size of ASTM No 7 or coarser.

| |||||

Physical properties of 304 grade stainless steel in the annealed condition

Grade

Density (kg/m3)

Elastic Modulus (GPa)

Mean Coefficient of Thermal Expansion (μm/m/°C)

Thermal Conductivity (W/m.K)

Specific Heat 0-100°C (J/kg.K)

Electrical Resistivity (nΩ.m)

0-100°C

0-315°C

0-538°C

at 100°C

at 500°C

304/L/H

8000

193

17.2

17.8

18.4

16.2

21.5

500

720

Grade

|

Density (kg/m3)

|

Elastic Modulus (GPa)

|

Mean Coefficient of Thermal Expansion (μm/m/°C)

|

Thermal Conductivity (W/m.K)

|

Specific Heat 0-100°C (J/kg.K)

|

Electrical Resistivity (nΩ.m)

| |||

0-100°C

|

0-315°C

|

0-538°C

|

at 100°C

|

at 500°C

| |||||

304/L/H

|

8000

|

193

|

17.2

|

17.8

|

18.4

|

16.2

|

21.5

|

500

|

720

|

Grade specifications for 304 grade stainless steel

Grade

UNS No

Old British

Euronorm

Swedish SS

Japanese JIS

BS

En

No

Name

304

S30400

304S31

58E

1.4301

X5CrNi18-10

2332

SUS 304

304L

S30403

304S11

-

1.4306

X2CrNi19-11

2352

SUS 304L

304H

S30409

304S51

-

1.4948

X6CrNi18-11

-

-

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

Grade

|

UNS No

|

Old British

|

Euronorm

|

Swedish SS

|

Japanese JIS

| ||

BS

|

En

|

No

|

Name

| ||||

304

|

S30400

|

304S31

|

58E

|

1.4301

|

X5CrNi18-10

|

2332

|

SUS 304

|

304L

|

S30403

|

304S11

|

-

|

1.4306

|

X2CrNi19-11

|

2352

|

SUS 304L

|

304H

|

S30409

|

304S51

|

-

|

1.4948

|

X6CrNi18-11

|

-

|

-

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

| |||||||

Type

Size

SMLS Elbow: 1/2"~24" (DN15 - DN600)

Wall thickness

sch10, sch20, sch30, std, sch40S, sch60,

Standards

ASME, ASTM, DIN, JIS, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Surface treatment

Transparent oil, rust-proof black oil or hot galvanized

Applications

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

NPS

O.D.

D

O.D.

D1

Center to End

C

Center to End

M

1 1/4 - 1/2

42.2

21.3

48

48

Type

| |

Size

|

SMLS Elbow: 1/2"~24" (DN15 - DN600)

Welded Elbow: 1/2"~48" (DN15 - DN1200)

|

Wall thickness

|

sch10, sch20, sch30, std, sch40S, sch60,

xs, sch80, sch100, etc

|

Standards

|

ASME, ASTM, DIN, JIS, etc

|

Material

|

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

|

Surface treatment

|

Transparent oil, rust-proof black oil or hot galvanized

|

Applications

|

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

|

NPS

|

O.D.

D |

O.D.

D1 |

Center to End

C |

Center to End

M |

1 1/4 - 1/2

|

42.2

|

21.3

|

48

|

48

|

ANSI B16.9 ASTM A403 WP304 Reducing Tee

ANSI B16.9 ASTM A403 WP304 Reducing Tee

1. They are manufactured to be used in flow lines for gases, fluids in industrial processes, medical, construction and many other specialized applications.

2. The 304 Reducing Tee is constructed of heavy materials for rigid applications like extreme high/low temperature resistance etc.

3. The 304 Reducing Tee is specifically designed for use on process and control systems, instrumentation, and equipment used in chemical, petroleum, fluid power, electronic and pulp and paper plants.

ANSI B16.9 ASTM A403 WP304 Reducing Tee's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ANSI B16.9 ASTM A403 WP304 Reducing Tee.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|