DIN EN 1092/1 Type 11 GR.2507 Weld Neck Flange DN50 PN100

DIN EN 1092/1 Type 11 GR.2507 Weld Neck Flange DN50 PN100

1. Material: 2507 (F53 / 1.4410 / UNS S32750)

2. Size: 2 Inch (DN50)

- FOB PriceUSD 1 - 1,900/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Size: 2 Inch (DN50)

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Standard or Nonstandard: Standard

- Material: 2507 (F53 / 1.4410 / UNS S32750)

- Technics: Forging

- Type: 2507 Weld Neck Flange

- Shape: Round

- Standard: DIN EN 1092/1 Type 11

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

1. Material: 2507 (F53 / 1.4410 / UNS S32750)

2. Size: 2 Inch (DN50)

3. Standard: DIN EN 1092/1 Type 11

4. Type: 2507 Weld Neck Flange

5. Pressure: PN100

Base on excellente quality, satisfactory service and reasonable prcie, yaang's products have exported to USA, Russia, Korea, Brazil, Chile, Peru and MId East, etc.

Super Duplex 2507 (F53 / 1.4410 / UNS S32750) has excellent corrosion resistance to a wide variety of media, with outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments, with Critical Pitting Temperature exceeding 50°C. UNS S32750 (F53 / 1.4410 / Alloy 2507) exhibits a low coefficient of thermal expansion and higher heat conductivity than austenitic steels and is suitable for working temperatures up to 300°C.

China Flange Manufacturer Yaang supplies DIN EN 1092/1 Type 11 GR.2507 Weld Neck Flange, DN50, PN100.

Chemical Composition of Grade Super Duplex 2507 (F53 / 1.4410 / UNS S32750)

| Grade | Chemistry (Typical Values) | Mechanicals | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | Cr | Ni | Mo | Cu | N | W | Si | Mn | P max | S max | C max | Fe | UTS N/mm² (min) | 0.20% Proof (min) | Elong % (min) | Hardness HB (max) | PREN |

| 2507 | 25.0 | 7.0 | 3.8 | 0.75 | 0.25 | 0.28 | 0.80 | 1.20 | 0.035 | 0.020 | 0.030 | Bal | 750 | 500-550 | 25 | 270 | 41 |

| DIN 2637 GR.2507 Weld Neck Flange | ||

| 1 | Material: |

Stainless Steel: such as 304, 304L, 316, 316L, 321 ,

310S, 904L, S31803, F51 and so on.

|

| 2 | Standard: | GB, JIS, BS, DIN, ANSI and Non standard |

| 3 | ANSI Class: | 15, 030, 040, 060, 090 |

| 4 | Size: | 1/2" - 24" |

| 5 | Type: |

Slip-on flanges, Blind flanges, Lap joint flanges,

Welding neck flanges,Plate flange,

Socket welding flanges and Treaded flanges

|

| 6 | Pressure ratings: |

Class: 150 300 400 600 900 1500 and 2500

PN: 6 10 16 25 40 64 and 160 , 5K - 40K and so on

|

| 7 | Sealing surface: | FF ,RF, LJ, FM , R.T.J , R.J and so on . |

| 8 | Production process: | raw material-cutting-heating-forging-heat treatment-maching-inspection. |

| 15 | Application: |

petroleum, chemical, power, gas, water, linepipe, heat exchanger,

shipbuilding, construction, etc.

|

| 16 | Tolerance: | not less than +_8% of normal wall thickness. |

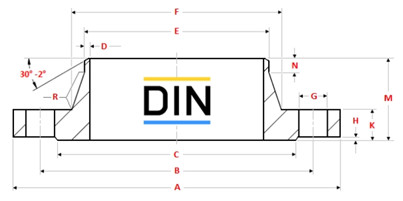

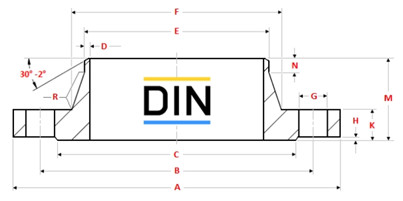

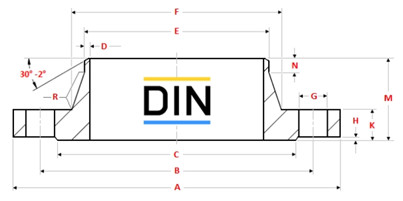

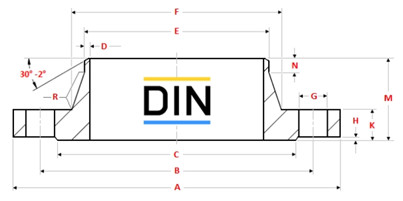

Dims Weld Neck Flanges -Type 11- PN 100 - DIN EN 1092/1

| DN | A | B | C | D | E | F |

| 10 | 100 | 70 | 40 | 2 | 17.2 | 32 |

| 15 | 105 | 75 | 45 | 3.2 | 21.3 | 34 |

| 20 | 130 | 90 | 58 | 3.2 | 26.9 | 42 |

| 25 | 140 | 100 | 68 | 3.6 | 33.7 | 52 |

| 32 | 155 | 110 | 78 | 3.6 | 42.4 | 62 |

| 40 | 170 | 125 | 88 | 3.6 | 48.3 | 70 |

| 50 | 195 | 145 | 102 | 4 | 60.3 | 90 |

| 65 | 220 | 170 | 122 | 4 | 76.1 | 108 |

| 80 | 230 | 180 | 138 | 5 | 88.9 | 120 |

| 100 | 265 | 210 | 162 | 5.6 | 114.3 | 150 |

| 125 | 315 | 250 | 188 | 6.3 | 139.7 | 180 |

| 150 | 355 | 290 | 218 | 8 | 168.3 | 210 |

| 200 | 430 | 360 | 285 | 8.8 | 219.1 | 278 |

| 250 | 505 | 430 | 345 | 10 | 273 | 340 |

| 300 | 585 | 500 | 410 | 12.5 | 323.9 | 400 |

| 350 | 655 | 560 | 465 | 14.2 | 355.6 | 460 |

| DN | A | B | C | D | E | F |

| DN | G | H | K | M | N | R |

| 10 | 14 | 2 | 20 | 45 | 6 | 4 |

| 15 | 14 | 2 | 20 | 45 | 6 | 4 |

| 20 | 18 | 2 | 22 | 48 | 8 | 4 |

| 25 | 18 | 2 | 24 | 58 | 8 | 4 |

| 32 | 22 | 2 | 24 | 60 | 8 | 6 |

| 40 | 22 | 3 | 26 | 62 | 10 | 6 |

| 50 | 26 | 3 | 28 | 68 | 10 | 6 |

| 65 | 26 | 3 | 30 | 76 | 12 | 6 |

| 80 | 26 | 3 | 32 | 78 | 12 | 8 |

| 100 | 30 | 3 | 36 | 90 | 12 | 8 |

| 125 | 33 | 3 | 40 | 105 | 12 | 8 |

| 150 | 33 | 3 | 44 | 115 | 12 | 10 |

| 200 | 36 | 3 | 52 | 130 | 16 | 10 |

| 250 | 39 | 3 | 60 | 157 | 18 | 12 |

| 300 | 42 | 4 | 68 | 170 | 18 | 12 |

| 350 | 48 | 4 | 74 | 189 | 20 | 12 |

| DN | G | H | K | M | N | R |

Indications:

- A = Outside Diameter

- B = Diameter of Bolt Circle

- G = Diameter of Bolt Holes

- C = Diameter of Raised Face

- H = Height of Raised Face

- E = Outside Diameter of Neck

- K = Flange thickness

- M = Length of Flange

- N = Length of right end

- F = Neck Diameter

- R = Radius of Corners

- D = Wall thickness

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Butt-weld ends (must be specified when ordering) acc. to DIN 3239-1-R6 edge form 22 to DIN 2559 (DIN EN ISO 9692)

Special notes:

- Hex bolt lengths and diameters & lengths of Stud Bolts are calculated by the author of this website.

- All lengths are calculated without washers, spring washers etc. and free threads (equals 1/3 time bolt diameter)

- All lengths are calculated with a gasket thickness of 3 mm.

- The dimensions of the bolts are calculated for the type 11 weld neck flange. Other types of flanges can be have

different bolt hole diameters and thicknesses, so that the bolts even can have different dimensions.

NOTE 1: ISO 7005-1 (steel flanges) PN 20, 50, 110, 150, 260, 420 are designed to be interchangeable with ASME B16.5 and MSS SP-44 flanges - ISO 7005-1 flanges are not identical to ASME B 16.5 and MSS SP 44 flanges but are deemed to comply with the dimensions specified in the ASME B 16.5 and MSS SP 44.

ISO 7005-2 (cast iron) flanges PN 20, 50 are designed to be interchangeable with ANSI/ASME B16.1 (gray cast iron) and B 16.42 (ductile cast iron) but they are not identical. They are deemed to comply with dimensions specified in ASME B16.1 (grey cast iron) and B 16.42 (ductile cast iron).

NOTE 2: ISO PN 2.5, 6 do not have a corresponding ASME class and ASME Class 75, 400 and 800 do not have corresponding ISO PN designation. The use of these PN and Class flange ratings are therefore not recommended.

Weld neck flange is a type of pipe flange that incorporates a cast-in neck that is welded to the pipe. Unlike a plain flange that is slipped over the pipe prior to being welded into place, a weld neck flange has a spout-like neck that is beveled to match up to the pipe. Once the pipe is beveled to match the weld neck flange, a perfect V shape is created in which a butt weld is placed to connect the two components.

APPLICATIONS:

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Where can we find the high quality DIN EN 1092/1 Type 11 GR.2507 Weld Neck Flange DN50 PN100.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited is a China WN Flanges Manufacturer).

If any inquiry about products, please feel free to contact us sales@yaang.com

If any inquiry about products, please feel free to contact us sales@yaang.com

Related products:More>>

|